Oil Filtraion

Generation 2 Filtration™ elements are used to remove particles ranging in sizes down to 1 micron and 99.97% water removal from the oil based fluid.

Oil does not wear out, it just gets dirty. The cleaner you can keep oil, the longer you can go between changes. With improved filtration, customers are able to safely maximize oil change intervals while achieving reduced engine wear, helping to reduce costs and environmental impact.

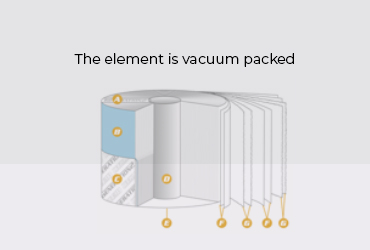

You need more than a standard oil and filter to extend engine life and time between oil changes. Generation 2™ ‘bypass’ filtration has the ability to polish small volumes of oil at slow flow rates, down to 1 micron, through the precision wound multi-ply ‘axial-flow’ cellulose element. This removes ultra-fine contamination and water normally missed by standard full-flow filters.

If the concentration of ultra-fine particles and acidity levels in oil remain low, you can prolong the oil and increase productivity, resulting in savings that go directly to the Bottom Line. Generation 2 FiltrationTM (G2F) addresses these concerns.

The earth has a limited supply of non- renewable resources that are depleting at alarming rates. With added pressure on industry to reduce environmental impact and the implementation of ISO 14001, G2F helps industry do their part to reduce waste oil and protect the environment for future generations.

The G2F Element - The Secret to our Success

Prolongs oil with operation safety

Minimizes engine wear and prolongs component life

Reduces new-unused oil and full-flow filter purchases

Reduces waste oil and waste oil disposal costs

Reduces downtime for oil maintenance

Detects coolant leaks and fuel dilution

Cleans oil 5 ISO grades cleaner than new unused oil

Reduces water concentration to less than 100 ppm

Maintains oil viscosity and acidity (TAN)

Prevents ‘fine tolerance valves’ from sticking

Dramatically extends oil and hydraulic component life